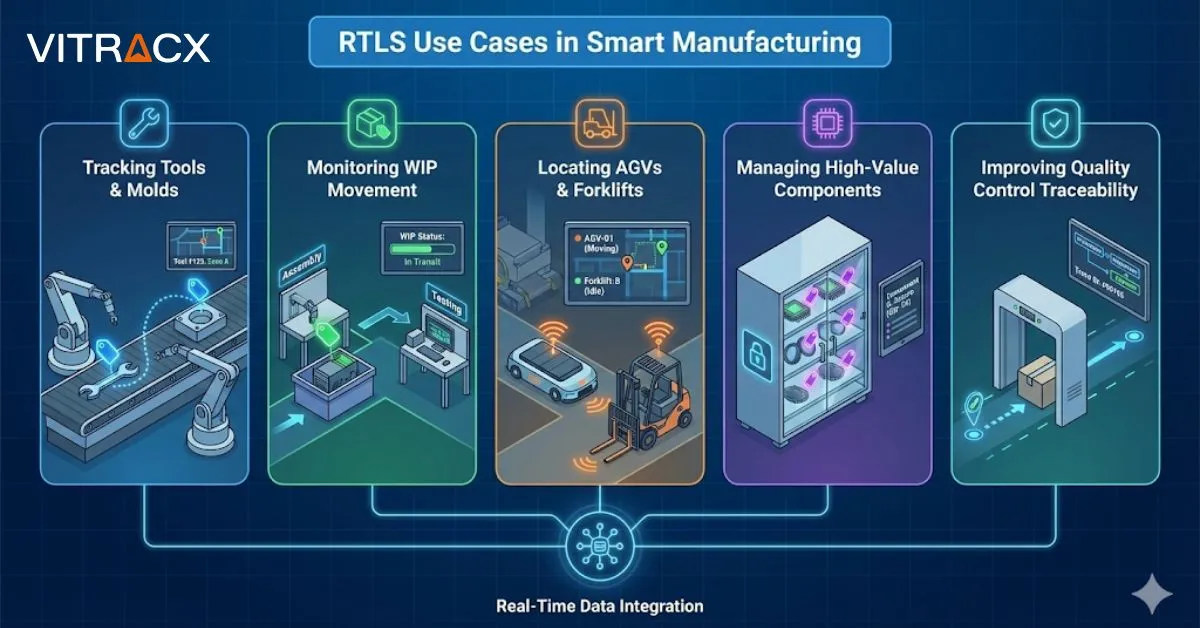

Smart manufacturing is transforming how factories operate by combining automation, real-time data, and intelligent decision-making. At the core of this transformation lies Real-Time Location Systems (RTLS)—a powerful technology that delivers live visibility of assets, materials, tools, and workflows across the manufacturing floor.

By integrating RTLS solutions for smart manufacturing, manufacturers can eliminate inefficiencies, reduce downtime, and gain complete operational control in highly dynamic environments.

What is RTLS in Smart Manufacturing?

RTLS (Real-Time Location System) is a technology that tracks the real-time location and movement of assets using wireless tags, sensors, and software platforms. In smart manufacturing, RTLS enables manufacturers to monitor machines, tools, raw materials, work-in-progress (WIP), and finished goods with precision.

RTLS solutions integrate seamlessly with smart manufacturing systems, supporting automation, Industry 4.0 initiatives, and data-driven production strategies.

Why RTLS is Essential for Smart Manufacturing?

Traditional manufacturing struggles with asset misplacement, production delays, and lack of real-time visibility. RTLS directly addresses these challenges by delivering continuous location intelligence and actionable insights.

Key Challenges Solved by RTLS

- Missing tools or components

- Production line bottlenecks

- Manual tracking errors

- Poor asset utilization

- Delayed maintenance

Top RTLS Benefits for Smart Manufacturing

1. Real-Time Asset Visibility

RTLS provides instant visibility of machines, tools, pallets, and materials across the factory floor. Operators no longer waste time searching for assets, ensuring uninterrupted production flow.

2. Improved Production Efficiency

With RTLS, manufacturers can track WIP movement in real time, identify bottlenecks, and optimize workflows. This leads to faster cycle times and higher throughput.

3. Reduced Downtime and Delays

RTLS enables quick access to required tools and components, minimizing idle time. Automated alerts notify teams when assets are idle, misplaced, or delayed.

4. Enhanced Asset Utilization

RTLS analytics reveal how often assets are used, idle, or underutilized. This helps manufacturers make informed decisions about asset allocation, procurement, and maintenance planning.

5. Predictive Maintenance Support

By tracking machine movement, runtime, and usage patterns, RTLS supports predictive maintenance strategies. Maintenance teams can act before failures occur, improving equipment lifespan.

6. Improved Worker Safety

RTLS improves safety by monitoring the movement of heavy machinery, forklifts, and personnel. Geofencing and real-time alerts help prevent accidents in hazardous zones.

7. Better Inventory & Material Flow Management

RTLS tracks raw materials and finished goods throughout the manufacturing lifecycle. This ensures accurate inventory levels, reduces overstocking, and improves material flow efficiency.

8. Seamless Integration with Smart Manufacturing Systems

RTLS integrates with ERP, MES, WMS, and IoT platforms, enabling centralized data visibility and automated decision-making across production systems.