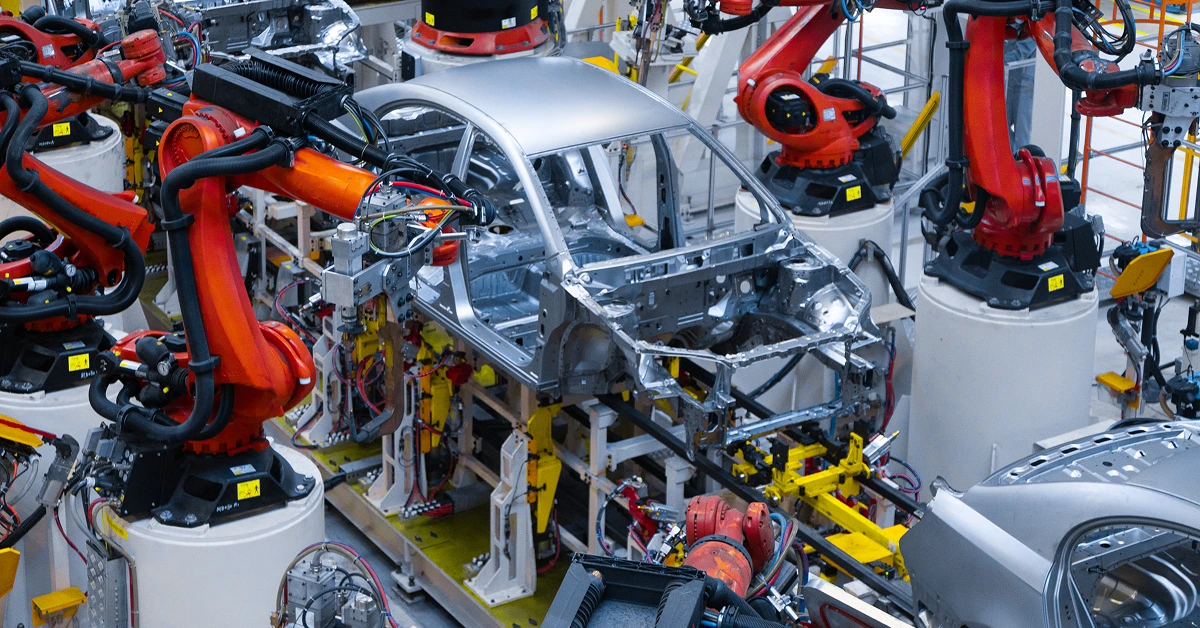

Automobile manufacturing has entered an era where precision, speed, and safety determine competitiveness. With increasing complexity across assembly lines and rising expectations for zero-defect production, manufacturers are embracing smarter technologies to support Industry and large-scale Digital Transformation efforts.

Among these technologies, Real-Time Locating Systems (RTLS) stand out as one of the most valuable advancements. They bring clarity to what was once invisible—real-time movement of tools, people, materials, forklifts, and vehicles.

Vitracx, a trusted provider of RTLS, RFID, and IoT solutions, delivers the real-time visibility automotive factories need to remain efficient, compliant, and safe.

Why Real-Time Visibility Matters in Automotive Manufacturing

Modern automotive factories operate like synchronized engines. Every tool, workstation, and employee plays a part in maintaining production flow. Yet common challenges often disrupt operations—tools misplaced during shifts, operators unsure of asset location, forklifts crossing paths without visibility, or workers accidentally entering high-risk zones.

These challenges might seem small individually, but collectively they create delays, accidents, and unnecessary downtime. RTLS solves these issues by making location data instantly available, enabling factories to operate with the precision that high-speed automotive production demands.

What Is RTLS and How Does It Fit into Industry?

At its core, RTLS (Real-Time Locating System) continuously tracks the position of tagged objects—whether tools, components, pallets, people, or forklifts. Unlike barcode scans or manual logs, RTLS updates automatically across the entire environment.

RTLS forms the backbone of many IIoT solutions by creating a digital layer of visibility. This makes it easier to automate workflows, analyze movement patterns, and align operations with the principles of Industrial Automation Solutions.

Different technologies power RTLS systems in automotive environments. Each serves a specific purpose:

| Technology |

Ideal Usage |

Accuracy |

Strength |

| UWB |

Tools, chassis, robots |

10–30 cm |

Precision |

| BLE AoA |

People, forklifts |

Sub-meter |

Reliable indoor tracking |

| BLE RSSI |

Zone visibility |

2–5 m |

Low-cost deployments |

| GPS + LoRa |

Yards, trucks |

Long range |

Outdoor coverage |

| RFID |

Item identification |

Point-based |

Low-cost visibility |

Combined under a unified platform like Vitracx RTLS, these technologies enable end-to-end visibility for every department—machine shops, assembly lines, paint shops, warehouses, and yards.

The Hidden Costs of Inefficient Tool and People Tracking

When tools go missing, production slows. When people enter unsafe zones, safety risks rise. When materials do not reach the right station on time, the entire line suffers.

A single misplaced torque wrench can delay a shift. A missing calibration tool can halt quality checks. Lack of visibility during emergencies complicates evacuation. These are not rare events—they occur daily in large factories.

RTLS minimizes these inefficiencies and creates a more predictable, controlled, and compliant environment. Automotive manufacturers see notable reductions in downtime, improved tool utilization, and better workforce safety within weeks of deployment.

Why Auto Manufacturers Are Moving from Traditional Tracking to RTLS

Traditional systems such as barcodes or manual registers depend heavily on human input. They work, but they don’t work fast enough for the dynamic nature of automotive factories.

RTLS eliminates manual steps by automatically updating the position of assets in real time.

This means:

- No waiting for someone to scan or log information

- No guesswork about where tools or workers might be

- No wasted minutes searching during production-critical phases

A quick comparison captures the difference:

| Feature |

Manual/Barcode |

RFID |

RTLS |

| Automation Level |

Low |

Medium |

High |

| Real-Time Tracking |

No |

Partial |

Yes |

| Accuracy |

Low |

Medium |

High (UWB) |

| Dependency on Human Action |

High |

Medium |

Low |

Automotive factories increasingly choose RTLS because it delivers continuous, accurate, and actionable location intelligence.

How RTLS Helps Auto Plants Secure, Track & Optimize

RTLS benefits appear in every corner of the factory. While the technology is powerful, its impact is even more remarkable when viewed on the shop floor.

Tool Tracking improves dramatically.

Instead of workers searching for tools, RTLS reveals their exact position in seconds. Unauthorized tool movement triggers alerts, helping prevent misplacement and accidental removal from defined zones.

People Tracking enhances safety and compliance.

Factories instantly know who is inside restricted areas, which team is present in a zone, and where each employee is during emergency evacuations. Panic buttons and geo-fencing further strengthen safety.

Forklift and MHE Tracking improves movement efficiency.

Forklifts are tracked in real time, allowing supervisors to evaluate utilization levels, avoid blind spots, and reduce collision risks.

Material Movement and WIP Visibility becomes effortless.

Chassis, engine assemblies, components, and finished goods can all be traced seamlessly from one stage to another.

All of these add up to a smarter, more connected environment aligned with Industry transformation goals.