Live Visibility. Faster Decisions. Industry 4.0-Ready Operations.

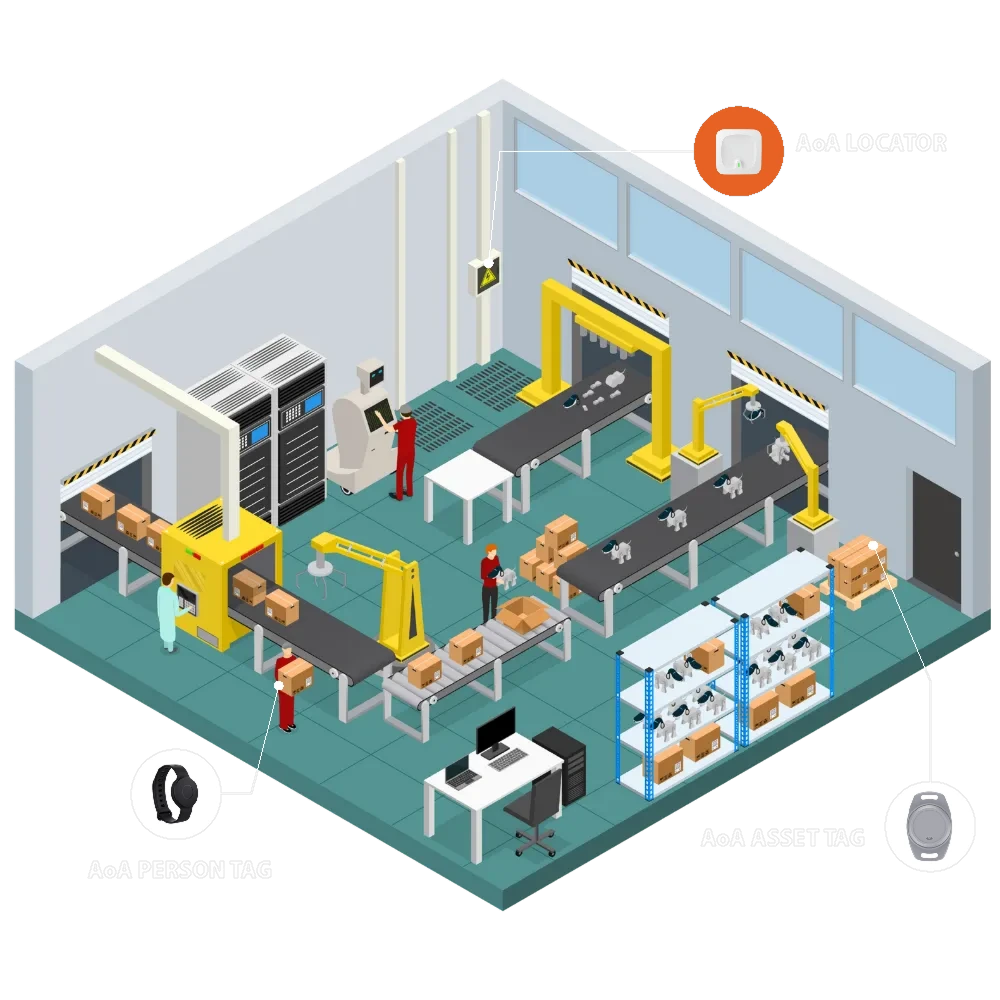

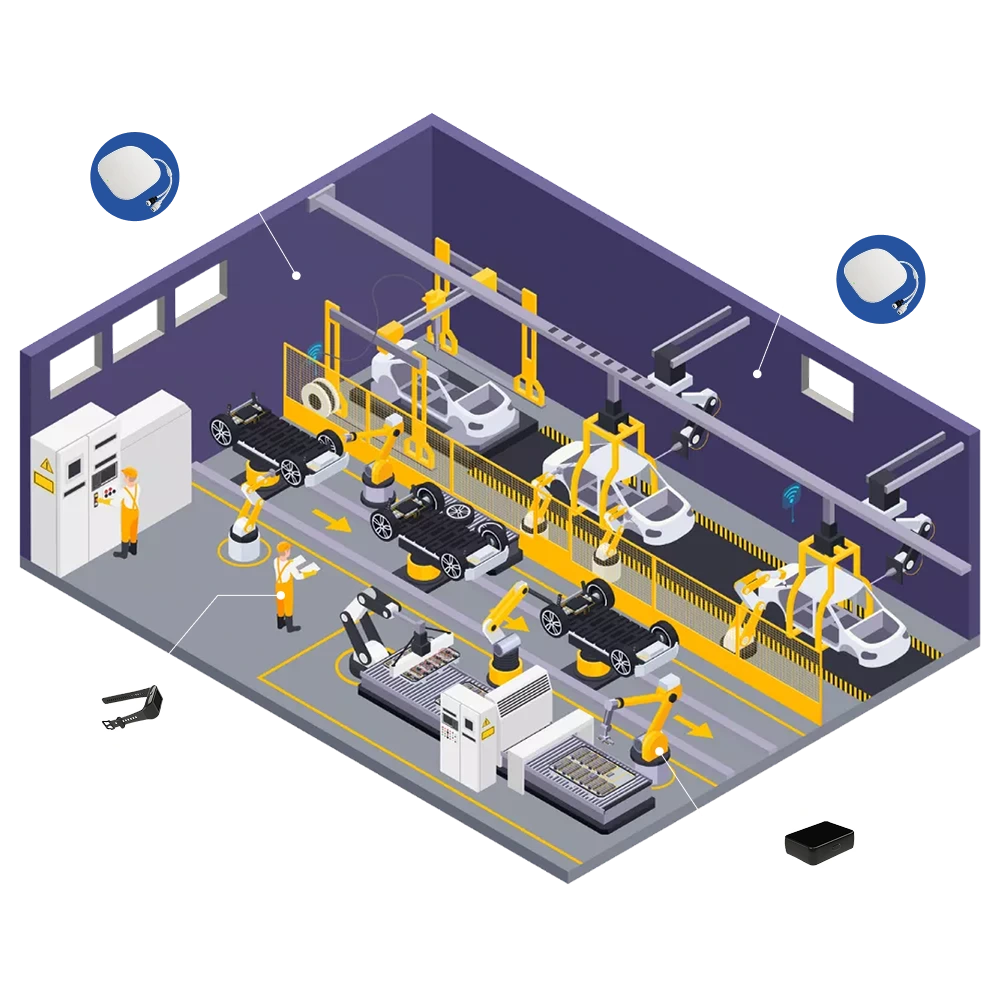

Unlock live visibility of assets, people, forklifts, WIP, tools, and trucks with an IIoT-driven RTLS platform designed for Digital Transformation and next-generation Industrial Automation.

RTLS (Real-Time Locating System) gives enterprises continuous, accurate, and real-time visibility across shopfloors, warehouses, hospitals, and large outdoor industrial yards.

Powered by BLE AoA, BLE RSSI, UWB, and GPS + LoRa, Vitracx RTLS delivers precise indoor–outdoor positioning, automated alerts, and deep operational insights—helping organizations reduce delays, improve productivity, enhance safety, and eliminate operational blind spots.

RTLS is a core enabler of Industry 4.0, providing the intelligence needed for smarter asset utilization, reduced search time, safer workplaces, and stronger data-driven decisions.

RTLS Key Advantages

How RTLS Enhances Industrial Operations

RTLS Technologies Supported

Industries Using RTLS

RTLS provides reliable, real-time automation and visibility across: